Tundish

Configuration:

To meet the requirement of clean steel production, high casting speed and near net shape casting development, and long life span of tundish, continuous casting refractories must be progress. Hitech Material provides a mature and effective solution for continuous casting tundish.

The role of the tundish is to stabilize the temperature of liquid steel and make the inclusions in liquid steel floating, in order to assure continuous casting process can smooth working when liquid steel is lacking in a short time or ladle is changing.

With the advancement of the continuous casting process, plus increasingly high requirement for quality of steel, consequently, the proportion of the clean steel and special steel in production is expanding.

To meet the requirement of clean steel production, high casting speed and near net shape casting development, and long life span of tundish, continuous casting refractories must be progress. Hitech Material provides a amature and effective solution for continuous casting tundish.

Continuous casting refractories should have the characteristics of high corrosion resistance, non-clogging, non pollution to liquid steel, and can even improve the liquid steel cleanliness.

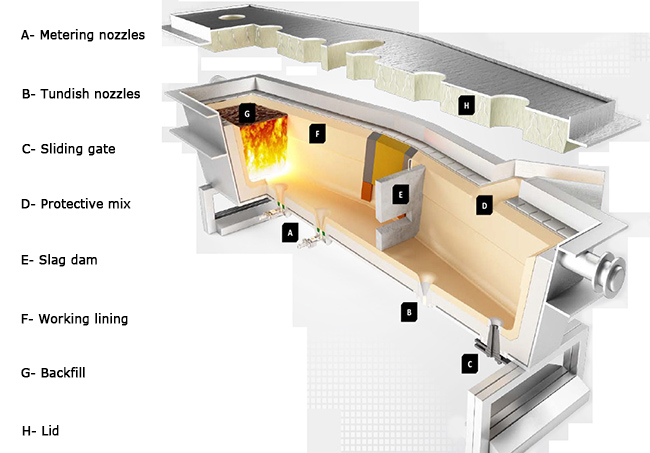

Insulation linings: fireclay bricks, insulating boards;

Permanent linings: high alumina low cement castables;

Working linings: MgO-based coatings, silica insulating boards, MgO-CaO ramming mass;

Lid: alumina-silicon castables;

Impact zone: high-alumina&MgO precast blocks, high alumina bricks, magnesia carbon bricks;

Slag dam: MgO-based & high-alumina slag dam.

2. Purifying liquid steel refractories

(1) Slag dam

In order to prevent formation of non-metal inclusions caused by roll steel slag, slag dam is installed in tundish.

At present, MgO-based slag dam is normally used, nevertheless, slag dam also has the trend of MgO-CaO based.

(2) Filter in T-shape tundish

Filter materials including: mullite, corundum, zircon, CaO-based, etc. Filter plays an important role in purifying liquid steel no matter what materials. CaO-based filter are relative best one.

(3) MgO-CaO coatings for tundish

MgO-CaO coatings for tundish can significantly reduce the level of oxygen and sulfur in liquid steel.

(4) Tundish nozzle

Tundish nozzles generally use corundum-mullite and alumina-carbon materials.

3. Continuous casting refractories

Stopper: alumina-carbon series of monolithic stopper;

Upper nozzle: alumina-carbon or fired mullite series;

Slide gate plate: alumina-carbon or alumina-zirconia-carbon series.